MDI 1

- 物性 测试标准 单位 数值 硬度 ASTM D2240 shore A 95 硬度 ASTM D2240 shore D 51 密度 ASTM D792 g/cm3 1.19 拉伸强度 ASTM D412(500mm/min) MPa 50 100%模量 ASTM D412(500mm/min) MPa 14.5 300&模量 ASTM D412(500mm/min) MPa 26 断裂伸长率 ASTM D412(500mm/min) % 420 撕裂强度 ASTM D264(500mm/min) N/mm 145 磨耗 DIN 53516 mm3 29 压缩永久变形(70℃ 24H) ASTM D395(方法B压缩率25%) % 21 压缩永久变形(100℃ 24H) ASTM D395(方法B压缩率25%) % 33 低温回缩TR10 GB/T7758-2002 ℃ -24 低温回缩TR30 GB/T 7758-2002 ℃ -15.7 低温回缩TR50 GB/T 7758-2002 ℃ -9.8

Material parameters

物性 测试标准 单位 数值

硬度 ASTM D2240 shore A 95

硬度 ASTM D2240 shore D 51

密度 ASTM D792 g/cm3 1.19

拉伸强度 ASTM D412(500mm/min) MPa 50

100%模量 ASTM D412(500mm/min) MPa 14.5

300&模量 ASTM D412(500mm/min) MPa 26

断裂伸长率 ASTM D412(500mm/min) % 420

撕裂强度 ASTM D264(500mm/min) N/mm 145

磨耗 DIN 53516 mm3 29

压缩永久变形(70℃ 24H) ASTM D395(方法B压缩率25%) % 21

压缩永久变形(100℃ 24H) ASTM D395(方法B压缩率25%) % 33

低温回缩TR10 GB/T7758-2002 ℃ -24

低温回缩TR30 GB/T 7758-2002 ℃ -15.7

低温回缩TR50 GB/T 7758-2002 ℃ -9.8

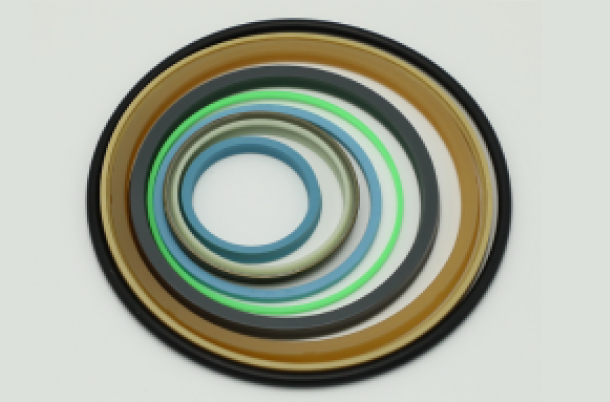

Material application scenarios

Working temperature: Polyformaldehyde POM -30-100 ℃, phenolic resin PF -55-120 ℃, filled PTFE+40% copper powder -200-260 ℃ Working temperature: Polyformaldehyde POM -30-100 ℃, phenolic resin PF -55-120 ℃, filled PTFE+40% copper powder -200-260 ℃ Working temperature: Polyformaldehyde POM -30-100 ℃, phenolic resin PF -55-120 ℃, filled PTFE+40% copper powder -200-260 ℃ Working temperature: Polyformaldehyde POM -30-100 ℃, phenolic resin PF -55-120 ℃, filled PTFE+40% copper powder -200-260 ℃ Working temperature: Polyformaldehyde POM -30-100 ℃, Phenolic resin PF -55-120 ℃, filled PTFE+40% copper powder -200-260 ℃, working temperature: POM -30-100 ℃, phenolic resin PF -55-120 ℃, filled PTFE+40% copper powder -200-260 ℃, working temperature: POM -30-100 ℃, phenolic resin PF -55-120 ℃, filled PTFE+40% copper powder -200-260 ℃, working temperature: POM -30-100 ℃, phenolic resin PF -55-120 ℃, Filled PTFE+40% copper powder -200-260 ℃

- About BORISE

- Company Profile

- About team

- on service

- Company Chronology

- Join us

- technical support

- Industry Solutions

- Technical Support Analysis

Copyright © 2022,All right reserved © Borise Technology Co., Ltddesign by:weetop